Our Industry Sectors

Wellbrock International Pvt. Ltd. has established a strong presence in major international markets by consistently delivering products that meet high standards of quality, safety, and reliability. At Wellbrock, we believe that tools should make work simpler, easier, and safer. To ensure this, we implement stringent quality control measures at every stage, from raw material selection to manufacturing and final packaging.

Our strength lies in our team's commitment to continuous product improvement by adopting the latest technologies. The result is high-quality Wellbrock tools and components. We welcome valuable suggestions and feedback from our customers, enabling us to make ongoing improvements.

INFRASTRUCTURE

Our success is underpinned by state-of-the-art manufacturing facilities that manage all stages, from raw material processing to the packaging of finished products. We also have a fully equipped R&D department, recognized by the Ministry of Science and Technology, Government of India. Production is carried out using the latest manufacturing techniques and processes, with only materials selected for their specific performance criteria. We dedicate the necessary resources to consistently produce products that exceed our standards. To maintain quality, inspections are conducted at every stage of the manufacturing and processing operations. Below is an overview of our production process:

• Stocking • Blanking • Heating • Forging • Broaching • Shot Blasting

• Automatic Wrench Grinding

• Adjustable Wrench Jaw Machining

• Hole Drilling • Induction Hardening • Vibratory Finishing

• Electroplating • Powder Coating.

Design & Tool Room

Our tool room is a key strength of our manufacturing process. Equipped with advanced CNC machining centers and the latest CAD/CAM software, we can manage even the most complex design requirements for forging, trimming, and coining dies. This capability ensures consistent quality and high-precision production.

Hot Forging

Our forging section is equipped with four Taiwan-made forging presses for high-accuracy forging, as well as 12 forging hammers. We follow the principles of Total Quality Management (TQM) to produce a wide range of precision-forged products.

Heat Treatment & Quenching

Heat treatment is the most critical process in our factory, as it determines the strength of each tool and component.

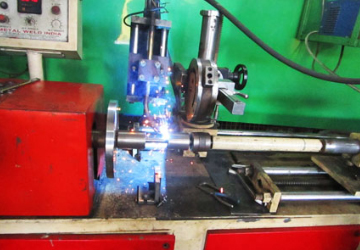

Machining

To achieve micron-level precision, our highly skilled employees use advanced CNC and NC machines for machining.

Surface Finishing & Coating

We handle surface finishing and coating in-house to ensure corrosion protection and superior surface quality.

Final Inspection & Packaging

Before dispatch, all products undergo a 100% inspection by our experienced staff to ensure they meet the highest quality standards.